Prevent Workplace Slips, Trips, and Falls—8 Safety Tips

Mopping up a spill or double-checking a guardrail might seem like simple common sense, but slips, trips, and falls are the second most common cause of death at work. These are life-saving procedures. Keep reading for practical tips to prevent workplace accidents.

These are familiar scenarios at home: slipping on a wet floor in the kitchen and tripping over a toy left out by the kids. While annoying, these accidents are typically minor hazards in the home. You might stub your toe, but rarely are there severe consequences.

In the workplace, it’s a different and far more serious story. Slips, trips, and falls account for over 200,000 workplace injuries per year. In 2020, nearly one in five accidents leading to missed work was due to a slip, trip, or fall. They’re also the second-leading cause of workplace fatalities.

As a safety leader, you’re responsible for your company’s duty of care and for providing a safe workplace. This blog post will examine common hazards leading to slips, trips, and falls and the steps you can take to minimize injury risks for your team.

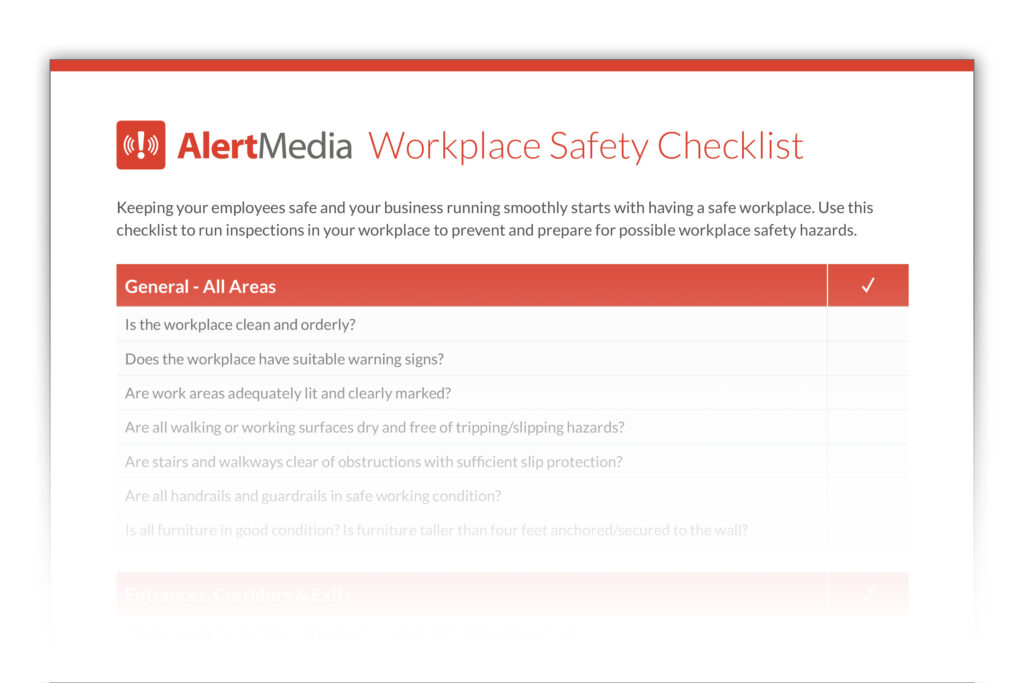

Download Our Workplace Safety Checklist

What Are Slip, Trip, and Fall Hazards in the Workplace?

Accidents involving slips, trips, and falls are often grouped together. While they’re similar, it’s important to understand the distinction since they each have different causes and consequences.

Slips occur when someone’s footwear loses traction with the surface they’re on, causing a loss of balance. Under some circumstances, slipping can lead to a fall.

Trips happen when someone hits their foot or lower leg on an object. As their upper body continues moving forward while their lower body remains stationary, the person may lose their balance in the process.

Falls often result from slips or trips, but they can also happen on their own. For example, a worker on a ladder or scaffolding can lose their balance and fall without slipping or tripping. Falls are also possible on flat surfaces and can still cause serious injuries.

Once you understand the hazards that lead to each type of accident, you can identify and mitigate risks in your workplace. Here are some of the most common causes of slips, trips, and falls in the workplace:

Slip Hazards

- Spills of wet or dry substances

- The cleaning process during spill removal

- Employees rushing or not paying attention to workplace conditions, especially while carrying objects

- Slippery floor surfaces such as marble or laminate

- Wet surfaces

- Poor lighting that obscures hazards

- Inappropriate footwear for the environment

- Transitioning between different types of surfaces

Trip Hazards

- Objects or obstructions in walkways

- Uneven surfaces on flooring or concrete

- Cables, cords, and hoses that aren’t properly secured or organized

- Unmarked steps or ramps

- Irregular stairs or stairs without railings

- Carpet, rugs, or mats with wrinkles or lifted edges

Fall Hazards

- Improperly used or poorly maintained ladders

- Elevated surfaces without guardrails

- Floor and wall openings

- Working in elevated environments without a safety harness

- Ill-fitting or improperly used PPE, such as helmets and safety lines

Preview the Workplace Safety Checklist

Are There OSHA Standards Related to Slips, Trips, and Falls?

Despite how common these injuries are, there is no specific OSHA standard on slips, trips, and falls. However, several OSHA rules indirectly address the same hazards.

The most important regulation to be aware of is 29 CFR 1910 Subpart D, which covers walking and working surfaces. OSHA updated the standard in 2017, introducing many upgrades to fall protection system requirements, improved employer-provided inspection guidelines, and a greater emphasis on safety training for employees.

For the construction industry, 29 CFR 1916 contains numerous fall-related regulations. Subpart M specifically addresses fall prevention, but other sections, such as Subpart L (scaffolds) and Subpart E (personal protective and lifesaving equipment), are also relevant. OSHA used 29 CFR 1916 as guidance when revising 29 CFR 1910, so the two guidelines now reflect many of the same OSHA violations.

As with any other workplace hazard or accident, OSHA recordkeeping requirements still apply in the event of a slip, trip, or fall incident. Internally, the reporting process is also an opportunity to review the details of the incident and determine how you can update your workplace safety policy to prevent similar accidents in the future.

How to Prevent Slips, Trips, and Falls in the Workplace

Many hazards that cause slips, trips, and falls are inevitable. However, injuries and accidents are not. To prevent slips, trips, and falls, train your employees to follow a three-step process:

- Recognize the hazard: Identify conditions that could lead to a slip, trip, or fall.

- Evaluate the hazard: Examine the situation and determine what level of risk it presents and who it affects.

- Control the hazard: Avoid the risk by removing the hazard (such as mopping up a spill) or implementing safety equipment and procedures (such as installing handrails on an elevated platform).

Here are eight workplace safety tips to prevent falls, trips, and slips.

1. Teach situational awareness

Since many causes of slips, trips, and falls are foreseeable, situational awareness in the workplace is one of the best preventative measures. Encourage your employees to pay attention to their surroundings and the risks they present:

- Look at walking surfaces for spills, obstacles, or other potential hazards

- Watch for signage that warns of increased hazards

- Be aware of conditions such as weather or time of day that might increase the risk of an accident

- Take shorter and more cautious steps on slippery surfaces

2. Encourage proper footwear

Like any other form of PPE, proper footwear can significantly reduce the risk of accidents. Research has found that slip-resistant shoes can reduce injury claims by 67% in environments with slippery work surfaces.

Employees should regularly inspect their shoes and make sure the soles aren’t worn out, as the lack of tread increases the danger of slipping. Additionally, anyone who works in conditions exposed to winter weather hazards should wear insulated boots. Cold temperatures can decrease muscle function, increasing the risk of slipping, tripping, or falling.

3. Utilize signage

Signage is an effective warning system for many workplace risks, but it can be especially effective in preventing slips, trips, and falls. There are two types of signs you can use to increase occupational safety:

- Temporary: Use warning signs while addressing a new hazard, such as cleaning up a spill, repairing a handrail, or replacing a ripped carpet. While temporary signage can help prevent injuries, you still need to address the actual hazard as quickly as possible.

- Permanent: For unavoidable hazards, such as slippery surfaces, a permanent sign can help warn employees to be careful. Use these sparingly, though, as it’s easy for people to ignore signs they see every day.

4. Keep floors clear and clean

Good housekeeping can help prevent most slips, trips, and falls. The details of keeping walking areas clean will vary widely by work environment, but there are a few common themes to encourage workplace safety:

- Report spills immediately, and warn nearby employees until someone can clean the contaminated surface

- Keep walkways clear of obstacles, loose objects, and anything that someone could trip over

- Place mats at entrances and exits so people can dry their shoes and avoid tracking water or other substances around the workplace

- Install handrails on stairways and elevated walkways

5. Apply non-slip mats and coatings

In some situations, keeping floors from becoming slippery is nearly impossible. Whether it’s liquid splashing or steam condensing, you must focus on mitigating the risk rather than avoiding it altogether.

For smaller or less demanding settings, non-slip mats can help employees maintain traction while walking around. In other cases, treating the floor with a permanent coating can help reduce slipping risks, even in the constant presence of liquids.

Who is at risk for slips, trips, and falls?

While all industries have some level of risk for a slip, trip, or fall, there are some industries where the risk is much higher, and the potential result could be much more dangerous. Here are some of the highest-risk industries:

- Construction

- Manufacturing

- Transportation/shipping/logistics

- Outdoor maintenance/groundskeeping

- Healthcare

- Foodservice/hospitality

6. Ensure proper lighting

To identify slip, trip, and fall hazards, your employees need to be able to see their surroundings. Make sure that all of your work areas have proper lighting, especially in areas that are more prone to unsafe conditions.

While this can be a challenge in outdoor work environments, especially at night, it’s even more critical in those situations. Environmental conditions can lead to increased risks, and employees need to be able to see and avoid them. Adequate lighting should also extend to parking lots and walking areas around your facilities.

7. Develop safety programs

Your company’s safety plans and programs should include specific guidelines for preventing slips, trips, and falls. There are a few key topics to consider when developing these policies:

- The types of surfaces employees work and walk on and whether they present extra risks

- Seasonal or regional conditions that could heighten hazards, such as winter weather threats

- Specific OSHA regulations that apply to your workplace

- Potentially hazardous equipment training such as ladder safety

- Regular inspection plans to ensure your team is maintaining a safe work environment

- Policies to report hazards using your company’s two-way communication platform

- First aid training, so employees are prepared to respond safely should injuries occur

8. Provide Slips, Trips, and Falls Training

Lastly, training your employees to avoid slips, trips, and falls will help keep them safe. Provide specific guidance on the environments they’ll work in and the hazards they’ll face. For example, a slips, trips, and falls safety talk for food service workers should focus on wet floors and walking safely in crowded, fast-paced environments. Conversely, office workers could use extra reminders to watch for stray power cords and keep walkways clear of boxes, files, and other tripping hazards.

Working slips, trips, and falls into your safety topics for meetings is also helpful. Regular safety talks or safety moments are an excellent opportunity to remind your team about seasonal risks or update them on newly installed safety measures.

Don’t Let Your Safety Standards Slip

Slips, trips, and falls are some of the most common workplace injuries. Fortunately, you can usually prevent them with proper planning and safety measures.

By making slip, trip, and fall prevention a part of your company’s safety culture, you can ensure your employees are aware of their surroundings and ready to look out for each other’s safety. Enable them to report hazards easily, address risks quickly, and train them to avoid situations that are likely to cause injury.

With the right planning and prevention, even the most intense work environments can be as safe as a walk in the park.